PLC programming

PLC programming

What do we offer?

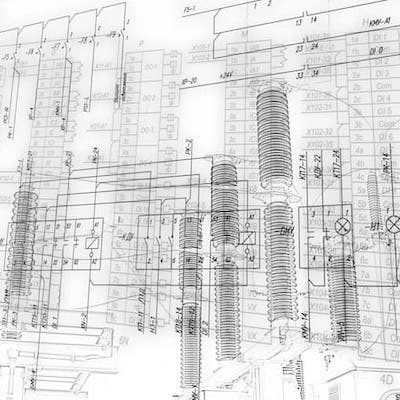

We offer a wide range of services related to PLC programming. Our staff is properly trained and has commercial experience in programming in various standards (OEM) and industry standards, e.g.: TMO, L7, V8, GSC, OVCS, Sicar, DCP, Integra 5,6,7, PackML, and others.

We implement non-standard solutions based on IEC 61131-3 and create a company standard that will help to standardize PLC programming and visualization wherever possible, improving the understanding of the code for maintenance departments and accelerating effective operation. We program controllers from Siemens, BOSH, Allen-Bradley, B&R, Beckhoff, Phoenix Contact, Omron, and Mitsubishi.

A bad PLC code modification can cost you a lot of money, time, and nerves. Leave it to us!

What does the cooperation look like?

We want to maintain transparency in every collaboration – we implement processes according to a planned and effective scheme.

INQUIRY

NEEDS ASSESSMENT

OFFER

SIGNING OF THE AGREEMENT

IMPLEMENTATION

PICKUP

Schedule a free technical consultation

Frequently asked questions (FAQ)

PLC programming is nothing more than writing a special “action plan” (software) that tells the machine how to behave—e.g., when to activate a sensor, start a motor, open an actuator, or move a component.

PLC programming is nothing more than writing a special “action plan” (software) that tells the machine how to behave—e.g., when to activate a sensor, start a motor, open an actuator, or move a component.

3 PLC programming is nothing more than writing a special “action plan” (software) that tells the machine how to behave—e.g., when to activate a sensor, start a motor, open an actuator, or move a component.

Other Services

PLC programming is nothing more than writing a special “action plan” (software) that tells the machine how to behave—e.g., when to activate a sensor, start a motor, open an actuator, or move a component.